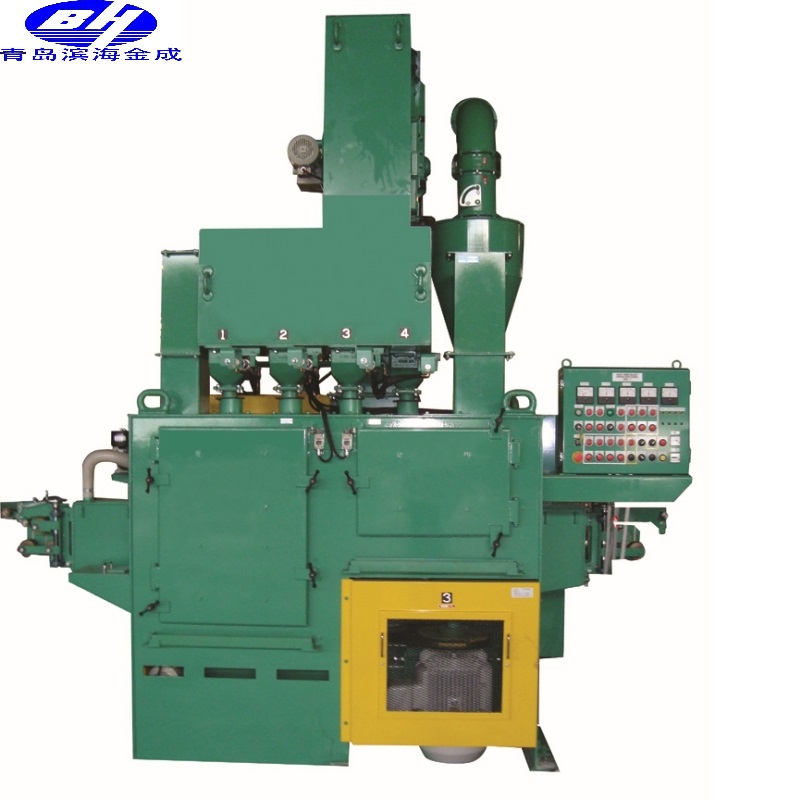

Igwe ihe na-agbawa agbawa nchara

Igwe ihe na-agbawa agbawa nchara

Steel pipe shot blasting igwe bụ a ọhụrụ ụdị pụrụ iche ogbunigwe akụrụngwa e mere ka onye ọrụ chọrọ, nke a na-pụrụ iche maka ihicha elu mgbidi nke nnukwu okirikiri ígwè ọkpọkọ na ifufe ike ifufe ụlọ elu, na n'ọnọdụ ụfọdụ ihicha n'ime na m mgbidi elu. nke ọkpọkọ ígwè.Site gbawara agbawa, ọ bụghị naanị nwere ike wepu nchara, ọnụ ọgụgụ, ịgbado ọkụ slag, nkedo ájá n'elu nke workpiece, ma ọ nwekwara ike ibelata esịtidem nchegbu nke workpiece, melite ike ọgwụgwụ nke workpiece, ime ka elu nke workpiece. ọla na ịbawanye elu nke workpiece Adhesion nke ihe nkiri agba n'oge eserese na-eme ka ọrụ mgbochi corrosion nke ọkpọ ígwè na gburugburu ígwè na-agbatị ma na-agbatị ndụ ọrụ nke workpiece.Na n'ikpeazụ nweta nzube nke melite dum elu na n'ime àgwà nke ọkpọkọ.

| data teknụzụ | QGW20-50 | QGW80-150 | |

| Dayameta tube dị mma (mm) | 30-500 | 250-1500 | |

| Ọ̀tụ̀tụ̀ asọba abrasive (kg/min) | 2X260 | 2X260 | 2X750 |

| Ọsọ nhicha (m/mim) | 0.5-4 | 0.5-4 | 1-10 |

isi atụmatụ nke ígwè anwụrụ ogbugba ịgbawa igwe

1. Ngwa ịgbawa agbawa agbawa agbawa agbagoro agbagoro nhazi.N'ihi na ala elu nke ígwè ọkpọkọ na dị iche iche diameters na-ebufe na ala table n'otu ịdị elu, ogbugba blaster Ome si ala ruo n'elu, na anya n'etiti abrasive na elu nke ígwè ọkpọkọ bụ ihu ọma otu, na. bụ, ihicha mmetụta bụ ihe edo.

2. The workpiece na-aga n'ihu na-agafe na ntinye na ntinye nke igwe na-agbawa agbapụ.N'ihi nhicha nke ọkpọkọ ígwè na nnukwu dayameta, iji gbochie abrasive ka ọ na-efe efe n'èzí, igwe na-eji ihe mkpuchi mkpuchi multi-layer replaceable iji nweta akara zuru oke na abrasive.

3. The ojiji nke centrifugal cantilever novel elu-arụmọrụ multi-arụ ọrụ ogbugba ogbunigwe igwe, nnukwu shot blasting ego, elu arụmọrụ, ngwa ngwa dochie agụba, na n'ozuzu nnọchi arụmọrụ, mfe mmezi.

4. Eserese abrasive e simulated (gụnyere mkpebi nke ihe nlereanya, ọnụ ọgụgụ na okirikiri nhọrọ ukwuu nke igwe na-agbawa agbawa) na eserese niile nke igwe agba agba agba na-adọta kpamkpam site na imewe enyemaka kọmputa.A na-emeziwanye ọnụego ojiji na nrụpụta ọrụ nke abrasive, a na-ahụta mmetụta ihicha ya, na uwe na-eyi na efere nchekwa ụlọ na-ebelata.

4. A na-eji ákwà mgbochi zuru oke BE-ụdị slag separator, nke na-eme ka ọnụọgụ nkewa dịkwuo mma, arụmọrụ nkewa na agba agba agba agba, ma na-ebelata ihe na-eyi na ngwaọrụ ọkụ ọkụ.

5. A na-eji efere ígwè Rolling Mn13 mee ihe maka nchebe n'ime ime ụlọ dị ọcha, a na-edozikwa efere nchebe site na mkpụrụ pụrụ iche.Ọ dị mfe ma dị mma iji dochie anya ma nwee ogologo ndụ ọrụ.

6.Na-ebufe ahịrị njikọ

The nnyefe linkage akara nwere ike na-aghọta stepless ọsọ iwu site ugboro Ntụgharị.Iji hụ na mgbe a na-agbapụ ọkpọkọ nchara nke nkọwa dị iche iche na ọsọ ọsọ a kapịrị ọnụ, ọkpọkọ ígwè ahụ nwere oge ntụgharị zuru ezu n'ime ụlọ ịgba ọkụ ọkụ iji nweta mmetụta kachasị mma.

A na-eme mgbanwe nke oghere rola site na ngwaọrụ na-edozi.A na-ejikọta otu rola ọ bụla site na mkpanaka njikọ, nke mere na enwere ike ime mgbanwe mmekọrịta.Enwere ike imezi usoro ngbanwe dị ka dayameta ọkpọkọ dị iche iche dị ka onye ọrụ chọrọ.

Rola ọ bụla nwere ike ịtụgharị gburugburu etiti ihe nkwado ahụ iji mezie akụkụ ya na ntụzịaka mbufe.Mgbe ọsọ nke roller na-adịgide adịgide, a na-agbanwe ọsọ mbufe na ntụgharị ntụgharị nke workpiece.A na-edozikwa akụkụ nke ihe a na-emegharị ahụ site na usoro ratchet na pawl.

A na-emepụta ike nke roller ọ bụla site na onye na-ebelata ya, a pụkwara ịhazi nọmba dị iche iche nke ndị na-ebelata ihe dị ka ike chọrọ.Oghere dị n'èzí nke roller bụ roba siri ike, nke nwere ma elasticity na eyi nguzogide ma nwee ike ịkwado ọkpọkọ ígwè nke ọma.

7, Steel ọkpọkọ na-anọgide na adiana.

8, The uzuzu mkpoko adopts gburugburu ebe obibi nchebe usu iyo katrij blowback uzuzu mkpoko.Onye na-anakọta uzuzu nwere nnukwu ebe nzacha na mmetụta nzacha dị mma.

9, The igwe imewe bụ akwụkwọ akụkọ na imewe, mfe iji na ịnọgide na-enwe.

10, Iji akpaka mmejọ nchọpụta ngwaọrụ na-aghọta akpaka shutdown mkpu ọrụ.Igwe a nwere njirimara nke usoro dị elu, nhazi ezi uche, ọrụ a pụrụ ịdabere na ya na mmepụta mmepụta dị elu.

11, Na-enweghị olulu Ọdịdị, mfe mmezi.

Igwe eji agba agba agba agba agba agba agba agba agba agba

1.usoro nhicha

Nbudata (onye ọrụ wetara) → ahịrị njikọ → banye n'ime ụlọ ịgba egbe → ịgbawa ọkụ (workpiece na-atụgharị mgbe ọ na-aga n'ihu)

Usoro okirikiri 2.Abrasive Circulation

Nchekwa abrasive → Njikwa ikuku → Mpempe ọkụ na-agbawa agbawa → mbuli elu ịwụ elu kwụ ọtọ → Nkewa Pellet → (Mmegharịgharị)

4. Njirimara nhazi

Ihe owuwu nke igwe ahụ nwere tebụl nri nri (mita 12), igwe na-agba agba agba, tebụl nri nri (mita 12), sistemu njikwa ikuku, sistemu njikwa ọkụ eletrik na sistem iwepu uzuzu.

Igwe na-agba agba agba bụ nke nwere ụlọ ịgba agba agba agba agba, mgbakọ ogbunigwe ogbunigwe, hopper na grille, onye na-agbapụta slag, igwe mbuli elu, ọdụ ụgbọ elu n'elu ikpo okwu, sistemu ọkụ ọkụ na ihe ndị ọzọ.